QDD Precision Manufacturing Co., Ltd.

- …

QDD Precision Manufacturing Co., Ltd.

- …

Welcome to QDD Precision Manufacturing

QDD provides one-stop specialized services for strategic customers from design, appearance, assembly testing, improving structure, mass production, etc., to provide customers with quality and affordable products, improve market competitiveness, thus achieving win-win value!

Processing Classification

Discover our integrated solutions for high-quality precision components in automotive, optics, medical, fluid control systems and automation.

CNC Machining

Precision machining for unmatched quality and reliability.

CNC Turning-Milling Composite Machining

High efficiency, precise.

Milling Processing

Precision drilling for enhanced accuracy and efficiency.

Lathe Machining

Accurate for rotational parts.

CNC Application Cases

Explore our cutting-edge precision manufacturing solutions tailored for diverse industries.

Application In The Automotive Industry

CNC is widely used in the automotive components industry, primarily for prototyping and mass production of precision metal and plastic parts such as engine components, transmission systems, and instrument panels. It achieves high precision, efficiency, flexibility, and consistency, making it suitable for manufacturing diverse components—from under-hood metal parts to interior trim prototypes.

Application In Optical Imaging Industry

Our high-precision optical components cater to the rigorous standards of the optics sector, delivering unparalleled clarity and precision in every lens and assembly. We utilize cutting-edge manufacturing processes and rigorous quality assurance protocols to ensure exceptional functionality and durability across diverse applications.

Application Cases In the Automation Sector

CNC machining produces the high-precision components—like robotic arms and sensor mounts—that power automated systems with reliability and repeatability. Our advanced techniques ensure that every part meets stringent industry standards, enhancing overall system efficiency.

Application Cases In Fluid Equipment Components

From design to production and assembly, we provide a comprehensive suite of services tailored to meet the needs of our strategic clients. Our experienced team is dedicated to enhancing your product's performance and reliability.

Application In The Medical

We manufacture critical components for medical devices, focusing on precision and reliability to ensure compliance with stringent health standards. Our expertise extends to custom solutions, allowing us to meet diverse client specifications and enhance product efficacy.

Application In The Sensor Industry

QDD CNC technology is utilized to fabricate sensor housings and internal components with high precision. For intelligent control, sensors are integrated to monitor critical parameters such as temperature, pressure, and vibration during the CNC machining process, ensuring consistent accuracy and quality.

Surface Treatment Solutions

Enhancing Durability and Performance

Anodizing Services

Our anodizing services enhance the corrosion resistance and surface hardness of metal components. This treatment is ideal for applications requiring durable and long-lasting finishes.

Polishing

We offer high-quality polishing services to provide a boosts shine for better aesthetics,Enhances corrosion resistance via a denser oxide layer,

Improves cleanability, suiting hygiene-sensitive fields like Medical & Healthcare.

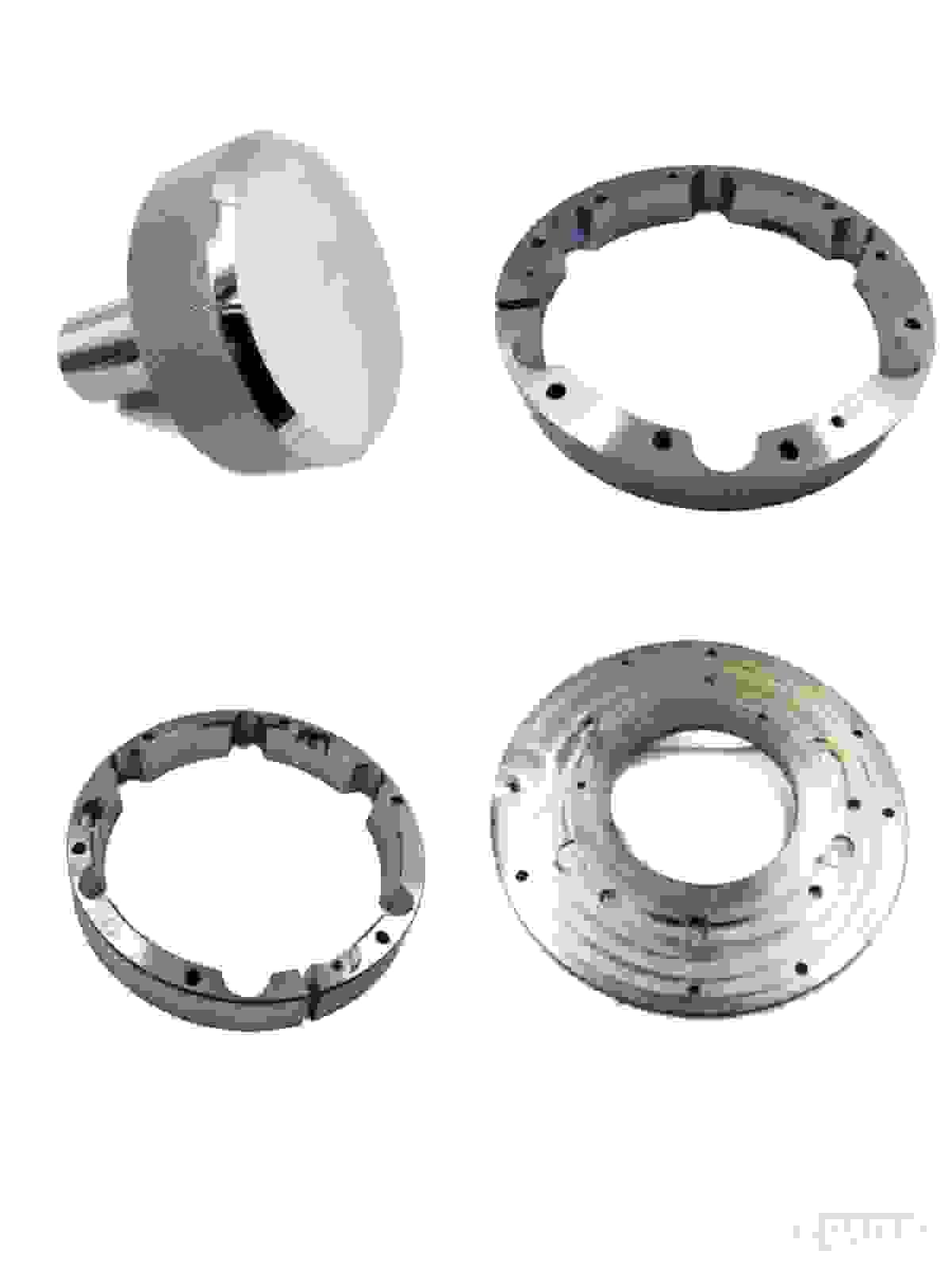

Electroplating

Our electroplating services improve the conductivity and appearance of components while providing an effective barrier against corrosion. This treatment is essential for precision parts in various industries.Machining Process

Streamlined Precision Manufacturing

1Customized

Provide samples or DXF/STEP/IGES drawings

2Engineering Quotation

Submit requirements for initial pricing

3Detail Coordination

Develop tailored solutions based on client needs to reach mutual agreement

4Prototype Validation

Dedicated sample production strictly adhering to client specifications

5Order & Payment

The Sign contract and proceed with payment after sample approval

6Manufacturing

We manufacture high-precision components tailored to your needs.

7Delivery & Completion

Manufacture products per contract terms, deliver accordingly, and confirm receipt to finalize the transaction

Subscribe to Our Newsletter

Join our mailing list to stay informed about our latest precision manufacturing solutions, industry insights, and special offers.

©2025 - Powered by QDD Precision Manufacturing Co., Ltd.