QDD Precision Manufacturing Co., Ltd.

- …

QDD Precision Manufacturing Co., Ltd.

- …

Over 15 Years of Expertise

2 production plants in Dongguan, China, totaling 6,500㎡.

Company Background

QDD Precision Manufacturing Co., Ltd. is a manufacturer (QDD) that provides precision metal parts machining, surface treatment, and assembly integration. QDD was established in Dongguan , and currently has two production bases, respectively located in Dongguan Dalingshan and Dongguan Qiaotou, covering a total area of about 6500 square meters.

About QDD Precision Manufacturing

QDD Precision Manufacturing Co., Ltd. is a manufacturer(QDD) to provides precision metal parts machining, surface treatment, and assembly integration. QDD was established in Dongguan, and currently has two production bases, respectively located in Dongguan Dalingshan and Dongguan Qiaotou, covering a total area of about 6500 square meters.

QDD specializes in automotive, semiconductor, optical, medical, fluid control system, automation mechanical precision components manufacturing. Precision components are mainly used in automotive transmission, semiconductor devices, optical lenses, medical equipment, sensors, valve bodies, automation, and other fields, covering design, production, assembly integrated supporting services, striving to become a respected precision parts production enterprise. QDD has CNC Machining and processing equipment, such as Japanese Brother Drilling and Tapping Machine, Japan Tsukami Turning and Milling Compound Machine, Taiwan Takazawa Turning and Milling Compound Machine, Dali, etc., and testing equipment such as Tokyo Precision 3D, Sanfeng Altimeter, Marriott anime, etc., providing a comprehensive guarantee for the production of high-precision parts!

QDD has more than 50 professionals, including 5 programming engineers, 3 process personnel, 5 quality inspection personnel, production technology more than ten people, the above personnel have more than five years of industry experience, QDD provides one-stop specialized services for strategic customers from design, appearance, assembly testing, improving structure, mass production, etc., to provide customers with quality and affordable products, improve market competitiveness, thus achieving win-win value!

Your Trust Mechanical Partner for

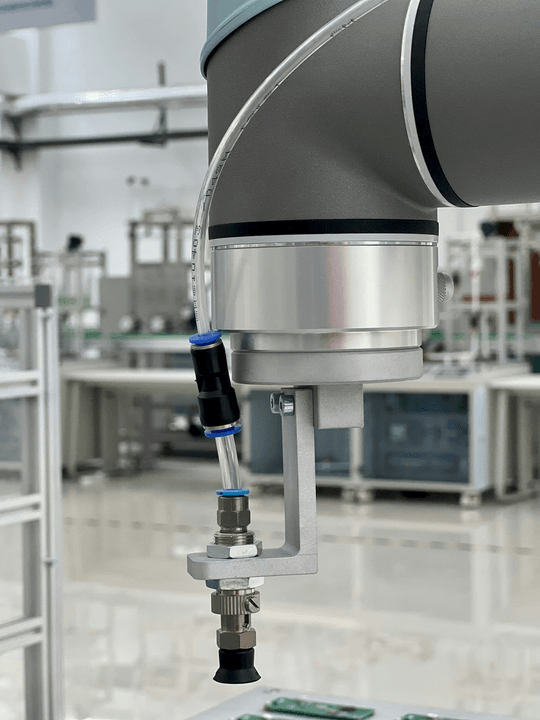

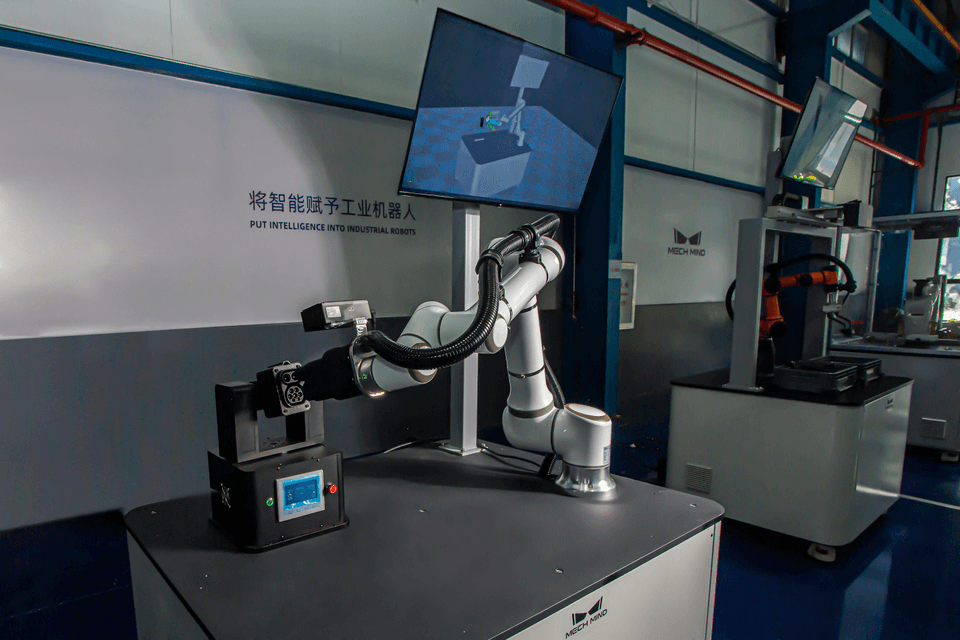

Precision CNC Machining

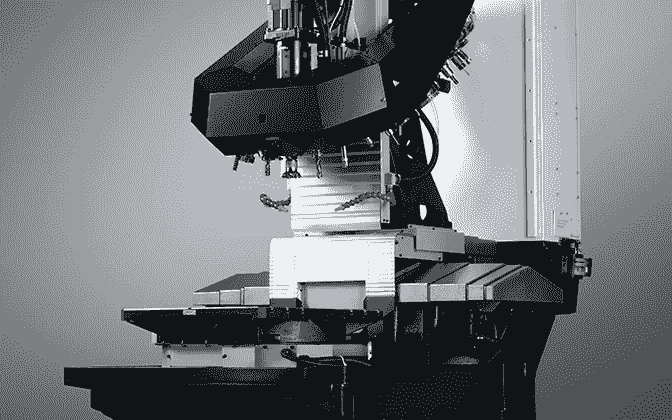

Our Machinery & Technical nfrastructure

QDD has more than 60+ CNC Machining and processing equipment, such as Japanese Brother Drilling and Tapping Machine, Japanese Tsukami Turning and Milling Compound Machine, a Taiwan Takazawa Turning and Milling Compound Machine, Dali, etc., and testing equipment such as Tokyo Precision 3D, Sanfeng Altimeter, Marriott anime, etc., providing a comprehensive guarantee for the production of high-precision parts!

Our Team of Professionals

QDD has more than 50 professionals, including 5 programming engineers, 3 process personnel, 5 quality inspection personnel, production technology more than ten people, the above personnel have more than five years of industry experience, QDD provides one-stop specialized services for strategic customers from design, appearance, assembly testing, improving structure, mass production, etc., to provide customers with quality and affordable products, improve market competitiveness, thus achieving win-win value!

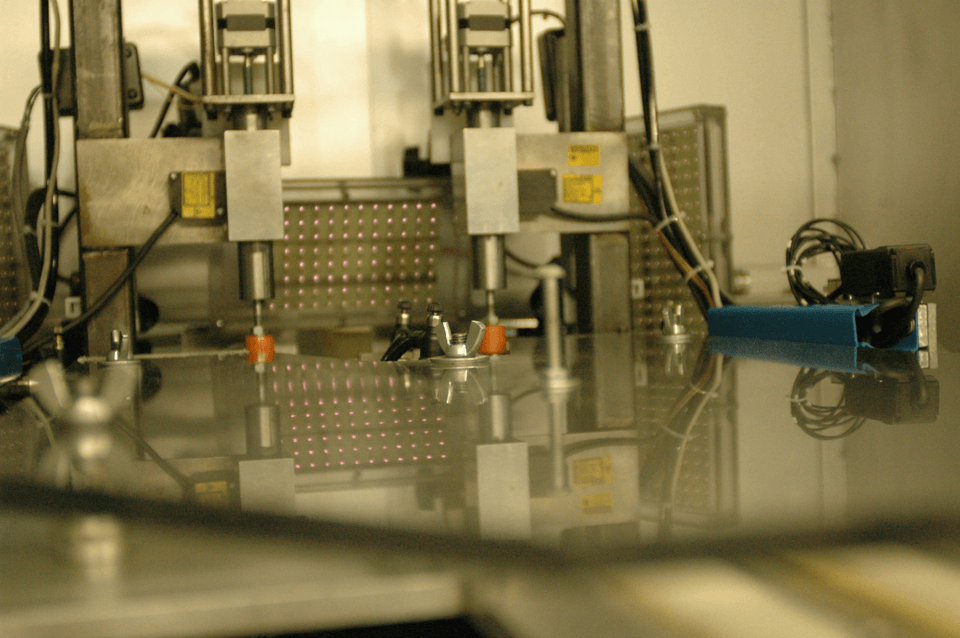

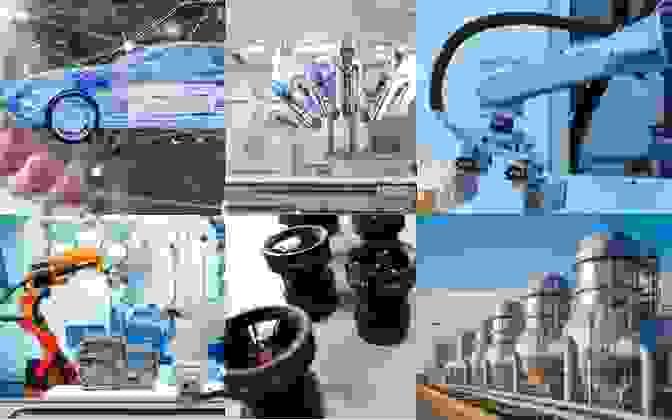

Capabilities & Applications

QDD specializes in automotive, semiconductor, optical, medical, fluid control system, and automation mechanical precision components manufacturing. Precision components are mainly used in automotive transmission, semiconductor devices, optical lenses, medical equipment, sensors, valve bodies, automation, and other fields, covering design, production, assembly integrated supporting services, striving to become a respected precision parts production enterprise.

What We Do?

Explore our cutting-edge precision manufacturing solutions tailored for diverse industries.

Precision Metal Parts Manufacturing

At QDD Precision Manufacturing Co., Ltd., we specialize in the meticulous fabrication of precision metal components. Our focus on automotive, optical, medical, and fluid control systems ensures that every part we produce meets the highest standards of quality and performance. We leverage advanced CNC machinery to deliver exceptional precision in every project we undertake.

Comprehensive Surface Treatment

We offer a full range of surface treatment services to enhance the durability and functionality of our components. Our expertise in various treatments ensures that our products not only meet but exceed industry standards, providing long-lasting performance in the most demanding applications.

Integrated Assembly Solutions

Our integrated assembly services provide customers with a one-stop solution for their manufacturing needs. From design, appearance, assembly testing, improving structure, mass production, etc., we work closely with our clients to optimize processes and improve product functionality, ensuring seamless assembly of complex.

Meet Our Experts

Focused on Delivering High-quality Manufacturing Solutions

Experienced Engineers

Our team includes highly skilled engineers with over five years of experience in the field. They possess the technical expertise necessary to tackle complex manufacturing challenges and ensure optimal outcomes for our clients.Quality Assurance Specialists

Our quality assurance personnel are committed to upholding the highest standards of excellence in every phase of the manufacturing process, guaranteeing that our products are reliable and precise.

Innovative Programmers

Our programming engineers bring innovative solutions to the table, utilizing state-of-the-art technology to streamline production and enhance efficiency, ensuring top-notch results.Quality Assurance Certifications

Ensuring excellence through certification.

ISO 9001 Certification

Our ISO 9001 certification demonstrates our commitment to maintaining a quality management system that meets international standards. This certification ensures that we consistently provide products that meet customer and regulatory requirements. By maintaining these rigorous standards, we enhance customer trust and satisfaction, ultimately driving our success in the competitive manufacturing industry.

Industry-Specific Compliance

We adhere to industry-specific compliance standards, ensuring that our manufacturing processes and products meet the stringent requirements of sectors such as automotive and medical devices. Our commitment to quality is further reinforced by regular audits and assessments, which help us stay ahead of industry trends and technological advancements.

Continuous Improvement Practices

Our dedication to continuous improvement is reflected in our quality assurance processes. We regularly review and enhance our manufacturing practices to ensure maximum efficiency and superior product quality. This proactive approach enables us to swiftly adapt to market changes and exceed client expectations consistently.

Contact Us

We are here to assist you with your precision manufacturing needs. Let's connect!

2nd Floor, No.13, North of Tiankengzi, Dalingshan Town, Dongguan City, Guangdong province, China.+86-18665175889

©2025 - Powered by QDD Precision Manufacturing Co., Ltd.