QDD Precision Manufacturing Co., Ltd.

- …

QDD Precision Manufacturing Co., Ltd.

- …

Your Premier Partner in OEM Machining Solutions

CNC Machinery

QDD Machinery specializes in the precision manufacturing of components tailored for industries such as automotive, optics, healthcare, and fluid dynamics.

Over 10 years of Experience In Crafting

High-accuracy Parts

- Rapid Prototype Lead Time: 3 Days

- Daily Production Capacity: 50,000 pieces

- Technology: equipped with cutting-edge 5-axis combined milling and turning tech.

About Us

QDD Precision Manufacturing Co., Ltd. is a manufacturer(QDD) to provides precision metal parts machining, surface treatment, and assembly integration. It was established in Dongguan, which is the international Manufacturing center, and currently has two production bases, respectively located in Dongguan Dalingshan and Dongguan Qiaotou, covering a total area of about 6,500㎡. QDD specializes in automotive, semiconductor, optical, medical, fluid control system, and automation mechanical precision components manufacturing...

Your Trust Mechanical Partner for Precision CNC Machining

10 Years of Specialization in High-Accuracy Machining Solutions

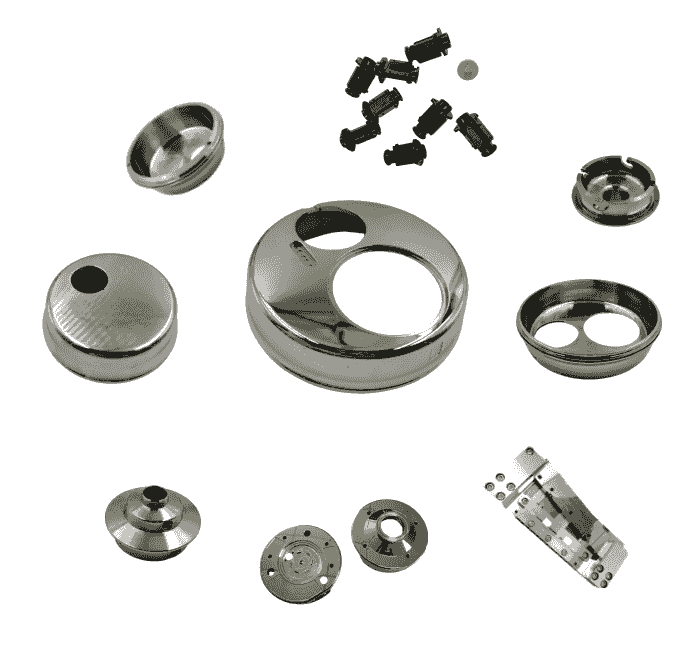

Automotive Industry

We provide high-quality precision parts for automotive applications, including drivetrain parts and sensors, helping manufacturers enhance vehicle performance.

Optical Sector

Our precision optical components are designed to meet the demanding needs of the optics industry, ensuring clarity and accuracy in every lens and assembly.

Medical Devices

We manufacture critical components for medical devices, focusing on precision and reliability to ensure compliance with stringent health standards.

Automation Sector

CNC machining produces the high-precision components—like robotic arms and sensor mounts—that power automated systems with reliability and repeatability.

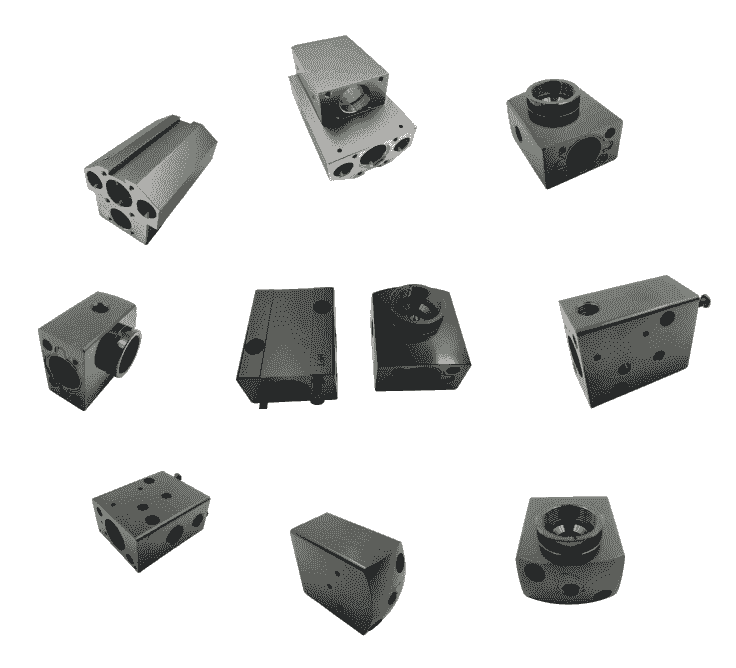

Fluid Equipment Components

CNC machining produces precise, reliable components for fluid systems—including valves, pumps, and manifolds—ensuring leak-proof performance in demanding applications.

Sensor Tech & Mechanical Sector

Our expert team fabricates sensor enclosures, mounts, and internal parts, ensuring precise tolerances for reliable signal detection and durability even in challenging environments.

4 Core Advantages | Comprehensive Support

10-Year Expertise in High-Precision CNC Manufacturing

2 Plants | 6,500㎡ Facility

- A Source Factory with 10 Years of Expertise, offering integrated design, production, and assembly services.

- Machining Process Categories: CNC Machining, Milling-Turning Compound Machining, Swiss-Type Automatic Lathe Machining, Horizontal Machining

Reliable Delivery

We guarantee on-time delivery with a fast turnaround to keep your projects on schedule.

Quality Assurance

High-Precision Production Equipment | Specialized in Automotive Transmission, Optical Lenses, Medical Devices, Sensors & Valve Bodies | Serving Hundreds of Successful Client Cases

Customized Solutions

- Applications: Automotive Components, Medical Devices, Optical Lens Parts, Sensor Technology, Fluid Control Systems, and the Automation Industry

- Diversified custom machining: 475 materials × 28 processes × 21 finishes × custom packaging.

- Zero-cost policies: Free process consultation + free modifications + free prototyping.

- Efficient after-sales: 30-minute response, 2-hour solutions, 24-hour issue resolution.

Comprehensive Service System

Thousands of Successful Cases

- Diversified Custom Machining = 475 Materials × 28 Processes × 21 Finishes × Custom Packaging

- 3 Zero-Cost Policies = Free Process Consultation × Free Modifications × Free Prototyping

- After-Sales: 30-Min Response, 2-Hour Solutions, 24-Hour Issue Resolution

Your Precision Partner

Explore Our Comprehensive Manufacturing Solutions

Why QDD Precision Manufacturing?

Your Trust Mechanical Partner for Precision CNC Machining

Experienced Professionals

- 50+ professionals with over 5 years’ experience, including 5 programming engineers, 3 process specialists, 5 QC inspectors, and 10+ production technicians.

- 1-5 days for prototype CNC machining; 7-15 days for small-batch production (up to 2,000 units).

State-of-the-Art Equipment

- We utilize advanced machinery from renowned manufacturers, ensuring that our production capabilities are cutting-edge.

- Our production capability is supported by a fleet of 60+ CNC machines from renowned brands like Brother, Tsugami, Takisawa, and TopWork.

Comprehensive Services

- We offer a one-stop solution that includes integrated services covering design, production, and assembly, striving to become a respected manufacturer of precision parts.

- These precision components are primarily used in automotive transmissions, optical lenses, medical devices, sensors, valve bodies, and other fields.

Customization: Advanced Policies & Diverse Solutions

- Diversified custom machining: 475 materials × 28 processes × 21 finishes × custom packaging.

- Zero-cost policies: Free process consultation + free modifications + free prototyping.

- Efficient after-sales: 30-min response, 2-hour solutions, 24-hour issue resolution.

Contact Us

We are here to assist you with your precision manufacturing needs. Let's connect!

©2025 - Powered by QDD Precision Manufacturing Co., Ltd.